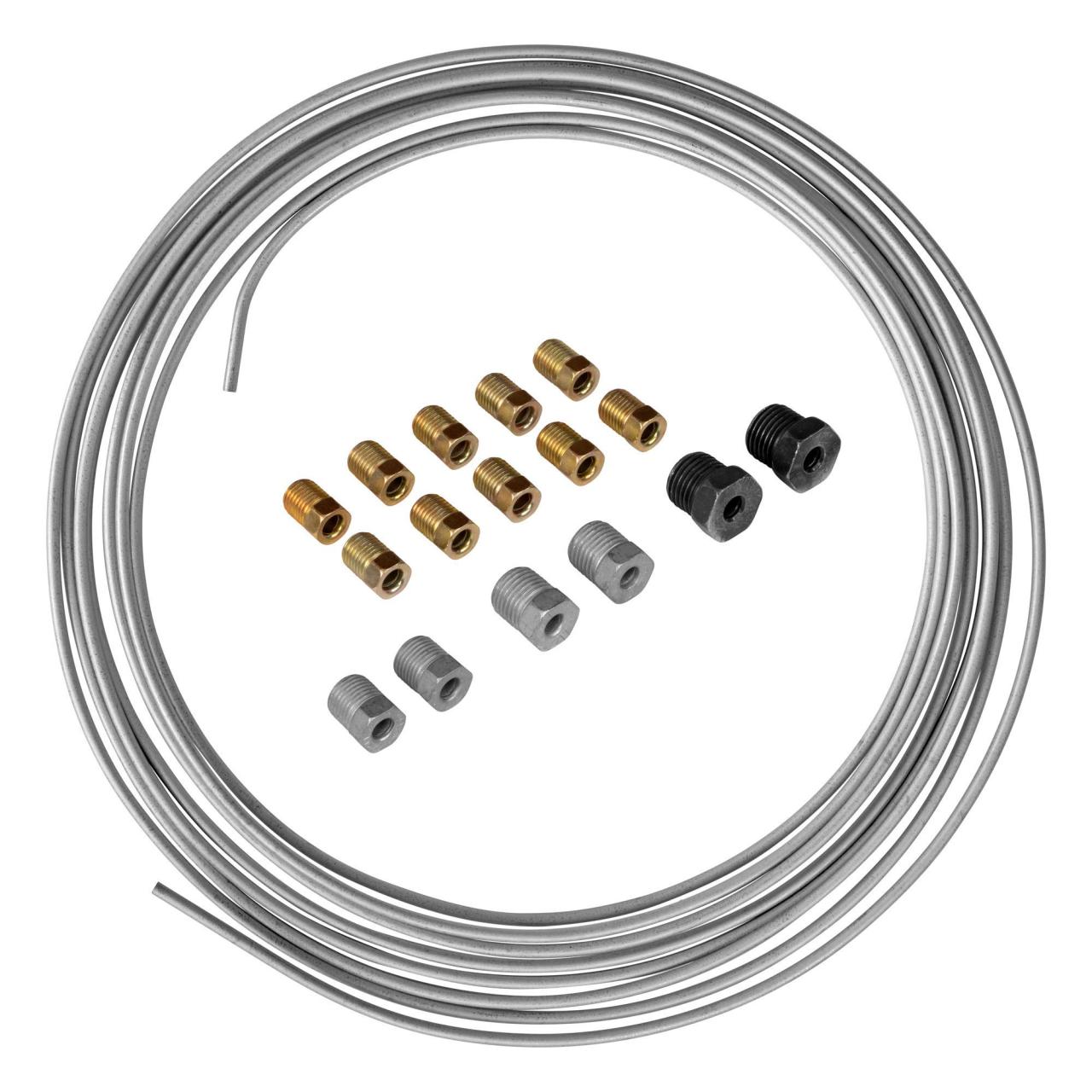

Welcome to the realm of 3/16 brake line compression fittings, where precision engineering meets automotive safety. Embark on a journey to unravel the intricate design, installation nuances, and industry standards that govern these essential components.

In this comprehensive guide, we’ll delve into the materials, applications, construction, installation procedures, advantages, disadvantages, maintenance, and troubleshooting of 3/16 brake line compression fittings. Join us as we navigate the technical intricacies of these fittings, ensuring a secure and reliable braking system for your vehicle.

Materials and Applications

3/16 brake line compression fittings are typically made from a combination of materials to ensure durability and corrosion resistance. The main components include:

- Body:Typically made of brass or stainless steel for strength and resistance to corrosion.

- Compression Nut:Usually made of brass or steel, it provides a tight seal against the brake line.

- Ferrule:A thin metal ring, typically made of copper or aluminum, that helps create a seal between the brake line and the fitting.

Applications

3/16 brake line compression fittings are widely used in the automotive industry for connecting brake lines. They are also employed in other industries, including:

- Hydraulic systems:For connecting hydraulic lines in industrial machinery and equipment.

- Refrigeration systems:To join refrigerant lines in air conditioning and refrigeration units.

- Pneumatic systems:For connecting air lines in pneumatic tools and equipment.

Design and Construction

3/16 brake line compression fittings are designed to connect brake lines securely and prevent leaks. They consist of three main components: the fitting body, the ferrule, and the nut.

Fitting Body

The fitting body is the main part of the fitting and is usually made of brass or stainless steel. It has a threaded end that connects to the brake line and a flared end that the ferrule and nut fit over.

Ferrule

The ferrule is a small, conical-shaped piece of metal that fits over the flared end of the brake line. When the nut is tightened, the ferrule is compressed, creating a seal between the brake line and the fitting body.

Nut

The nut is a hexagonal-shaped piece that fits over the ferrule and tightens it against the fitting body. The nut is usually made of brass or stainless steel and has a knurled surface for easy gripping.

Installation Procedures: 3/16 Brake Line Compression Fitting

Installing 3/16 brake line compression fittings requires careful attention to detail and the use of the appropriate tools. By following these step-by-step instructions, you can ensure a secure and leak-free connection.

Before starting the installation, gather the necessary tools and materials, including the brake line compression fitting, brake line, tubing cutter, flaring tool, wrench, and penetrating oil.

Cutting the Brake Line, 3/16 brake line compression fitting

Measure and cut the brake line to the desired length using a tubing cutter. Ensure that the cut is clean and perpendicular to the line’s axis.

Flaring the Brake Line

Insert the cut end of the brake line into the flaring tool and tighten the jaws to create a flared end. This flared end will provide a secure seal against the compression fitting.

Assembling the Compression Fitting

Apply penetrating oil to the threads of the compression fitting. Slide the compression nut and ferrule onto the brake line, followed by the compression fitting.

Tightening the Compression Fitting

Use a wrench to tighten the compression nut onto the fitting. Ensure that the nut is tightened sufficiently to create a leak-free seal, but avoid overtightening, as this can damage the fitting or brake line.

Testing the Connection

Once the compression fitting is installed, test the connection by applying pressure to the brake line. Check for any leaks or seepage. If any leaks are detected, tighten the compression nut further or replace the fitting as necessary.

Advantages and Disadvantages

Compression fittings offer several advantages over other types of brake line fittings. They are relatively easy to install, requiring only a few simple tools. They are also very versatile and can be used with a variety of different brake lines.

Additionally, compression fittings are relatively inexpensive, making them a cost-effective option.

Are you in need of the right plastic tubing size for bleeding brakes? This article provides valuable information on the appropriate tubing size to ensure an efficient and effective brake bleeding process.

Advantages

- Easy to install

- Versatile

- Inexpensive

Disadvantages

However, compression fittings also have some disadvantages. They can be more prone to leaks than other types of fittings, especially if they are not properly installed. Additionally, compression fittings can be difficult to remove once they have been installed, making it difficult to service or replace brake lines.

- Prone to leaks

- Difficult to remove

Maintenance and Troubleshooting

Maintaining 3/16 brake line compression fittings is crucial for ensuring proper brake performance. Regular inspections and timely repairs can extend their lifespan and prevent costly repairs down the road.

To maintain these fittings, inspect them periodically for signs of wear, corrosion, or leaks. Clean them thoroughly with a degreaser and inspect the sealing washers for any damage. Replace damaged washers promptly.

Troubleshooting Common Issues

- Leaking Fittings:Tighten the fitting using a wrench, but avoid overtightening. Replace the sealing washer if necessary.

- Damaged Threads:If the threads are stripped or damaged, the fitting must be replaced.

- Corrosion:Clean the fitting with a wire brush and apply an anti-corrosion spray to prevent further damage.

- Loose Fittings:Tighten the fitting using a wrench, ensuring it is secure without overtightening.

Industry Standards and Regulations

The automotive industry has established specific standards and regulations for 3/16 brake line compression fittings to ensure their safety, reliability, and performance.

Looking for a hydrating and revitalizing skincare solution? Consider the Good Molecules Hyaluronic Acid Serum . This serum deeply penetrates the skin, providing intense hydration and plumping effects, leaving your skin feeling soft, smooth, and radiant.

Adhering to these standards is crucial as it guarantees that the fittings meet the necessary specifications and requirements for proper brake system operation.

Standards Organizations

- SAE International (SAE):Develops and publishes standards for various automotive components, including brake line fittings.

- American National Standards Institute (ANSI):Accredits and coordinates standards developed by various organizations, including SAE.

- Department of Transportation (DOT):Enforces regulations related to vehicle safety, including brake systems.

Concluding Remarks

As we conclude our exploration of 3/16 brake line compression fittings, remember that their proper installation and maintenance are paramount for optimal brake performance. By adhering to industry standards and regulations, you can ensure the safety and reliability of your vehicle’s braking system.

Embrace the knowledge gained from this guide, and may your future automotive endeavors be smooth and secure.

Questions Often Asked

What are the advantages of using 3/16 brake line compression fittings?

3/16 brake line compression fittings offer several advantages, including ease of installation, secure connections, and durability. They provide a leak-proof seal and can withstand high pressure, making them ideal for automotive braking systems.

How often should I inspect my 3/16 brake line compression fittings?

Regular inspection of your 3/16 brake line compression fittings is crucial for safety. Inspect them at least once a year or more frequently if you drive in harsh conditions. Look for any signs of corrosion, leaks, or damage, and replace any faulty fittings promptly.

Can I install 3/16 brake line compression fittings myself?

While it is possible to install 3/16 brake line compression fittings yourself, it is recommended to seek professional assistance if you are not mechanically inclined. Improper installation can compromise the safety and reliability of your vehicle’s braking system.